Contents

ToggleBrief introduce

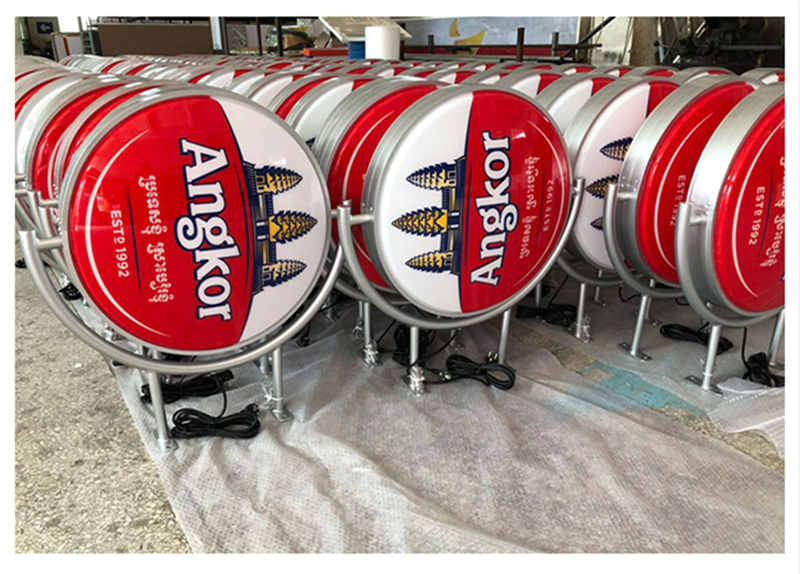

As a common form of outdoor advertising, the production process of pole light boxes requires multiple steps.

Following will introduce production process of pole light boxes in detail.

Production process of pole light boxes

Design stage

When designing a street pole light box, you need to consider factors such as size, shape, color, font, pattern, etc. of light box.

You also need to consider factors such as brightness and weather resistance of light box.

After design is completed, it needs to be confirmed with customer to ensure that customer’s requirements are met.

Material selection stage

Production of pole light boxes requires use of various materials, such as light box cloth, PVC board, aluminum alloy, stainless steel, etc.

When selecting materials, appropriate materials need to be selected based on design requirements and actual needs.

For example, light box cloth needs to be made of high-definition and highly weather-resistant materials, and aluminum alloy and stainless steel need to be made of high-quality materials to ensure durability and beauty of light box.

Processing stage

Processing stage includes cutting, bending, welding, grinding and other processes. These processes need to be carried out according to design requirements and relevant standards to ensure that light boxes produced meet requirements.

Corresponding equipment and tools need to be used when cutting and bending, and welding quality and surface finish need to be ensured when welding and grinding.

Assembly stage

During assembly, each component needs to be assembled and fixed according to design requirements to ensure structural stability and safety of the pole light box.

When assembling, you also need to consider installation method and

factors such as height of light box to ensure effectiveness and safety of light box.

Installation stage

During installation, light box needs to be fixed in corresponding position and flatness and stability of light box must be ensured.

Factors such as wind and earthquakes also need to be taken into consideration during installation to ensure safety and stability of light box.

At the same time, issues such as wire connections and power supply need to be considered to ensure that light box can be used normally.

Acceptance stage

During acceptance, appearance and quality of light box need to be checked to ensure that light box meets the design requirements and relevant standards.

At the same time, functional testing is also required to ensure the effectiveness and safety of light box.

After passing acceptance inspection, light box needs to be delivered to the customer, and customer will be provided with corresponding after-sales service and technical support.

Conclusion

In short, production process of pole light boxes requires multiple steps, and each step needs to be operated in accordance with design requirements and relevant standards to ensure that light boxes produced meet requirements and are of high quality and durability.