Contents

ToggleWhat is full acrylic light box

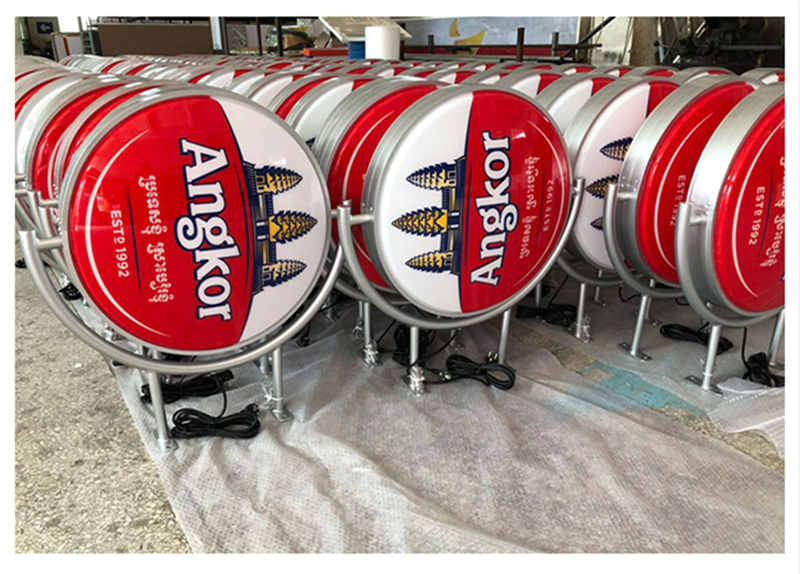

Full acrylic light box is made of acrylic board, and built-in light strip light source, which presents an overall luminous effect when turned on. Overall luminous effect is dreamy and eye-catching, and acrylic board has strong weather resistance.

Full acrylic light box can resist ultraviolet rays and rainwater, and maintenance is easy and not often.

It is one type of very popular light box in recent years.

So how is full acrylic light box made?

There are generally with following steps.

Steps for making full acrylic light box

- Design and create a production file for size and style of illuminated full acrylic light box, and import the file into production equipment.

- Preparation materials: acrylic board, LED beads (LED strip), adhesive (organic glue).

- According to size and shape of full acrylic light box required by customer, carve and stamping acrylic board to create desired style and size.

- After acrylic board is made, use a UV printer to print logo or text that needs to be displayed on surface of full acrylic light box, or use transparent stickers to stick it on.

- Use adhesive to evenly arrange LED beads onto back panel of one of acrylic boards.

- Combining and bonding 4 acrylic panels, it is best to use a needle to stick them together, so that glue will not overflow everywhere and affect appearance of lightbox.

- After the bonding is completed, power on to check lighting effect of full acrylic light box. If it works normally,

production is completed.

Conclusion

Above are production steps for full acrylic light box.

If you have any questions about them, please feel free to contact us at any time.